Receiver vertical BV900/810-1,0-16

Stamp-welded cylindrical steel receiver for compressed air with a working pressure of 1.6 MPa

Warranty period – 18 monthsThe Customs Union Certificates

Receiver vertical BV500/608-1,6 – 50

Stamp-welded cylindrical steel receiver for compressed air with a working pressure of 1.6 MPa

Warranty period – 18 monthsThe Customs Union Certificates

Receiver horizontal BV500/608-1,6 -03

Stamp-welded cylindrical steel receiver for compressed air with a working pressure of 1.6 MPa

Warranty period – 18 monthsThe Customs Union Certificates

Tank for a forklift

Oxygen valve

Vapor Phase Selection Valve KPF-1 (multipurpose valve)

| Specifications | Meaning |

|---|---|

| Working medium | Hydrocarbon liquefied fuel gas for municipal household consumption in accordance with GOST 20448-2018 |

| Working pressure, no more than | 1.6 MPa |

| Conditional bore 7mm | 7 mm |

| Input connection 1.1.1. 3/4” - 14 NPT | 3/4” - 14 NPT |

| Output connection | 885” - 14 NGO-LH-INT (or M22x1.5L) |

| Operating ambient temperature | -40°…+45 °С |

| Weight, no more than | 0,95 kg |

| Reliability indicators – mean time between failures, not less – average service life, not less | 10000 cycles; 12 years |

| Torque of force for screwing the valve into the neck of the cylinder | 220±40 Nm |

| The moment of force on the flywheel for hermetically closing the valve | 4,7Nm |

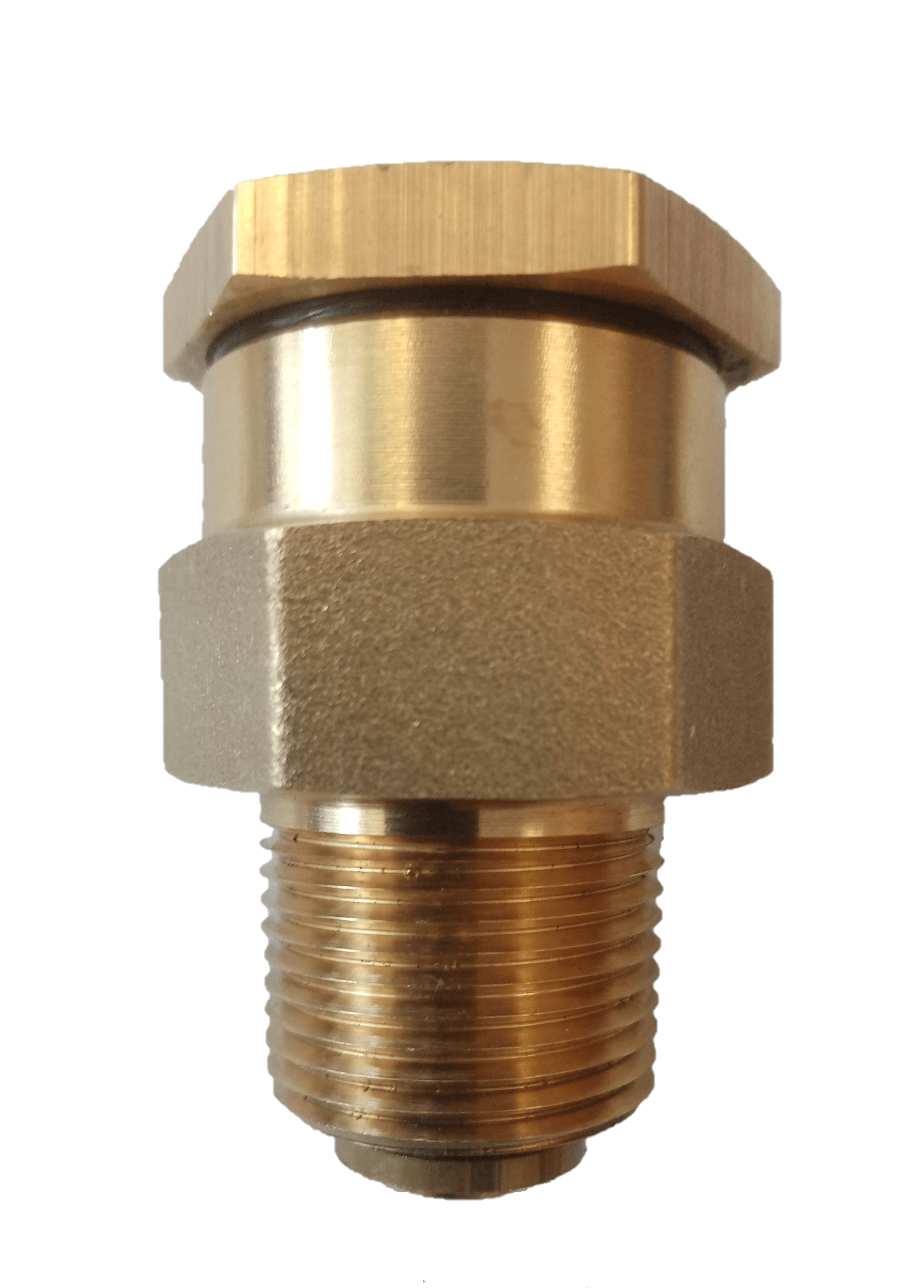

External safety valve KPn-2 and check valve (lower) KOn-2

| Parameter name | Safety valve KPn-2 | Check valve KOn-2 |

|---|---|---|

| Working environment | Hydrocarbon liquefied fuel gas for municipal household consumption according to GOST 20448 | Hydrocarbon liquefied fuel gas for municipal household consumption according to GOST 20448 |

| Working pressure (no more), MPa | 1,6 | 2,5 |

| P op - opening pressure (no more), MPa | 1,75 | - |

| P fo - full opening pressure (no more), MPa | 1,85 | 1 |

| Operating ambient temperature | -40°…+45°С | -40°…+45°С |

| Conditional bore, mm | 25 | 25 |

| Throughput at P but (not less), m3/min | 75 | 75 |

| Weight (no more than), kg | 0,8 | 0,5 |

| Input connection | 1” - NPT | 1 1/4” - NPT |

| Output connection | - | 1” - NPT |

| Reliability indicators: – mean time between failures (not less); - average service life (not less), years | 1000 cycles; 12 | - |

| Key size, mm | 55 | 46 |

| Screwing force moment, N∙m | 260±50 | 350±70 |

Filling Valve KN3

| Specifications | Meaning |

|---|---|

| Working medium | Hydrocarbon liquefied fuel gas for municipal household consumption in accordance with GOST 20448-2018 |

| Maximum gas working pressure | 2,5 МPа |

| Regulated throughput of the valve at a pressure of 0.1 MPa | min 33.5 l/min |

| Operating ambient temperature | -40°…+45°С |

| Operating ambient temperature | К 1 1/4'' GOST6111 |

| Outlet thread | 1 3/4 - 6 ACME 2G outer |

| Weight | Not more than 0,55 кg |

| Reliability indicator – time between failures | At least 5000 cycles |

| Average service life | At least 12 years |

| Moment of force of screwing the valve into the neck of the container | (350±40) Nm |

| Wrench size | 46 mm |

Liquid Withdrawal Valve KZHF1

| Specifications | Meaning |

|---|---|

| Working medium | Hydrocarbon liquefied fuel gas for municipal household consumption in accordance with GOST 20448-2018 |

| Maximum gas working pressure | 2,5 МPа |

| Working ambient temperature | -40°…+45°С |

| Connection thread with tank | K 3/4'' GOST6111 |

| Outlet thread | K 3/4'' GOST6111 internal |

| Weight | Not more than 0,75 кg |

| Reliability indicator – time between failures | At least 5000 cycles |

| Average service life | At least 12 years |

| Moment of force of screwing the valve into the neck of the container | (220±40) Nm |

| Wrench size | 32 mm |

Drain Valve KS1

| Specifications | Meaning |

|---|---|

| Working medium | Hydrocarbon liquefied fuel gas for municipal household consumption in accordance with GOST 20448-2018 |

| Maximum gas working pressure | 2.5 MPa |

| Operating ambient temperature | -40°…+45°С |

| Connection thread with tank | K 3/4'' GOST6111 |

| Outlet thread | K3/4'' GOST6111 internal |

| Weight | not more than 0,35 кg |

| Reliability indicator – time between failures | at least 5000 cycles |

| Average service life | at least 12 years |

| Moment of force of screwing the valve into the neck of the container | (220±40) Nm |

| Wrench size | 36 mm |