LPG storage tanks

Advantages of Mini-tank for LPG storage tanks:

-

Low cost of equipment and installation;

-

Does not require expensive excavation work;

-

The volume of gas in the container is 500 l. equivalent to 10 and 50 liter cylinders. Gas tanker refueling;

-

Installation of containers up to 600 l. directly next to the wall of a residential building (according to clause 8.2.3 of the code of rules for gas distribution systems SP 62.13330.2011);

-

It is possible to install a Minigas tank with a volume of up to 600 liters. on a trailer for self-refueling at a gas filling station (does not require additional permits according to the European rules for the transportation of dangerous goods “ADR”).

Design, production and quality control of cylinders is carried out in accordance with the requirements of ISO 9001: 2008. Certificate

Mini-tank for LPG storage tanks

Mini-tank for LPG storage is a low-cost solution for heating of your country-house. The mini-tank is supplied with high-quality shut-off valves manufactured in Italy that secure its safe operation.

Technical data on the Mini-tank for LPG storage:

Traditionally the large-size LPG storage tanks (of 2 000 litres and more) imply considerable prices that cannot be afforded by average owners of country houses, as well as costly underground installation.

In these terms a mini-tank is an attractive option. Firstly, such a container involves a lot more viable capital expenditures. Secondly, when buying our mini-tank for gas storage you get rid of daily gas filling.

Thus, the offered LPG storage tank volume facilitates from 2 weeks to 2-months of trouble-free heating (consumpion depends on the square footage of your house).

Certificates and warranty:

Mini-tank for LPG torage is certified in accordance with the standards of the Customs Union. Warranty period is 18 months. Service life is 24 years.

- Working environment – liquefied gas (propane, butane);

- Working pressure 1,6 МPа (16,0 kgf/cm2);

- Testing pressure 2,5 МPа (25,0 kgf/cm2);

- Burst pressure of at least 5,0 МPа (50,0 kgf/cm2).

- Low cost of equipment and installation.

- Doesn`t require costly excavation procedures.

- Volume in 500-liter tank is equivalent to 10 50-liter LPG bottles. Filling with LPG truck-carrier.

- Mini-tank (up to 600 l) installation next to wall of dwelling. (according to p.8.2.3 of regulations code for gas distribution systems СП13330.2011).

- Possible mounting of mini-tank for LPG storage (volume up to 600 l) on trailer for autonomous filling at gas-filling station (as per “European Agreement concerning the International Carriage of Dangerous Goods by Road” it doesn`t require additional permits).

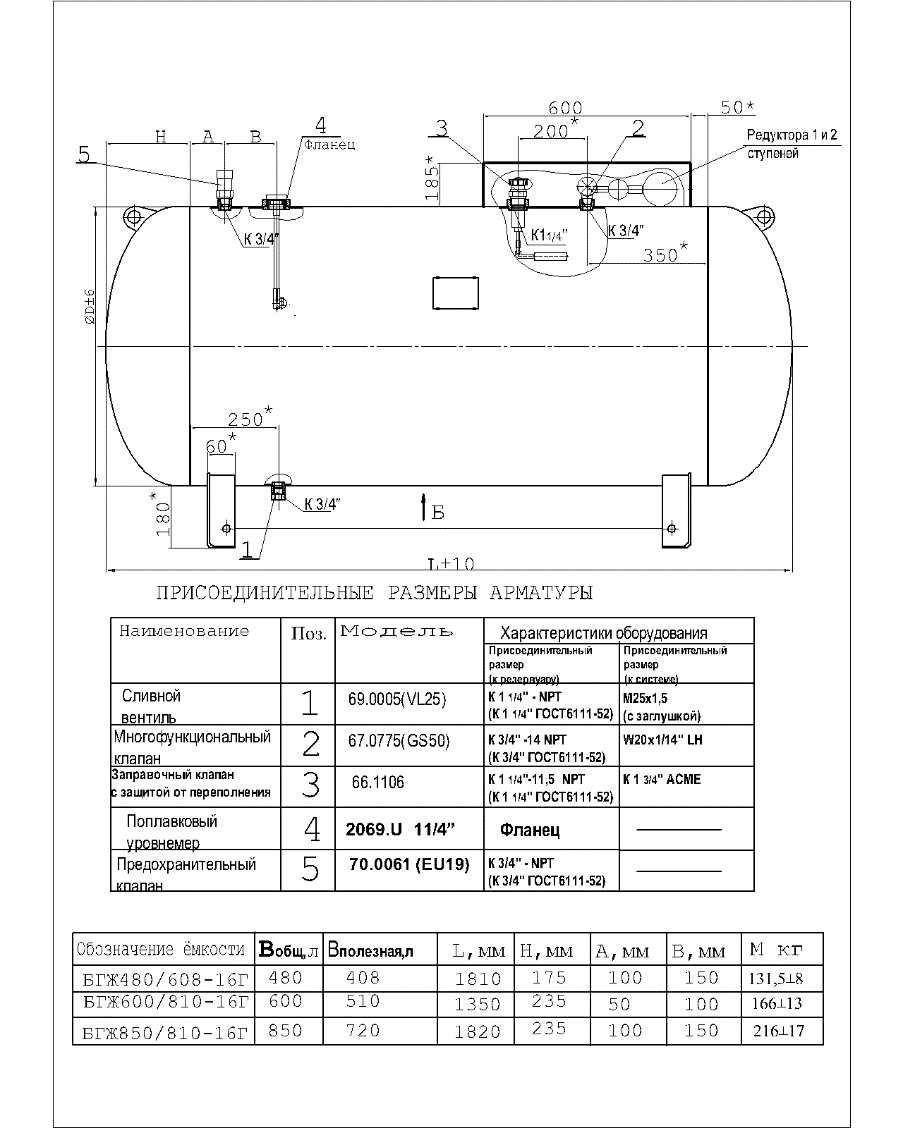

| Model | V total (l) | V useful (l) | L (mm) | Н (mm) | А (mm) | В (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|

| BGZH 480/608-16Г | 480 | 408 | 1810 | 175 | 100 | 150 | 131,5±8 |

| BGZH 600/810-16Г | 600 | 510 | 1350 | 235 | 50 | 100 | 166±13 |

| BGZH 850/810-16Г | 850 | 720 | 1820 | 235 | 100 | 150 | 216±17 |

Technical characteristics of automobile cylinders:

-

containers are certified;

-

containers are produced using modern Italian equipment;

-

shut-off valves manufactured and tested using high-tech Italian equipment are installed on the tank;

-

100% radiographic inspection of welded joints;

-

anti-corrosion coating.

Design, production and quality control of cylinders is carried out in accordance with the requirements of ISO 9001: 2008. Certificate

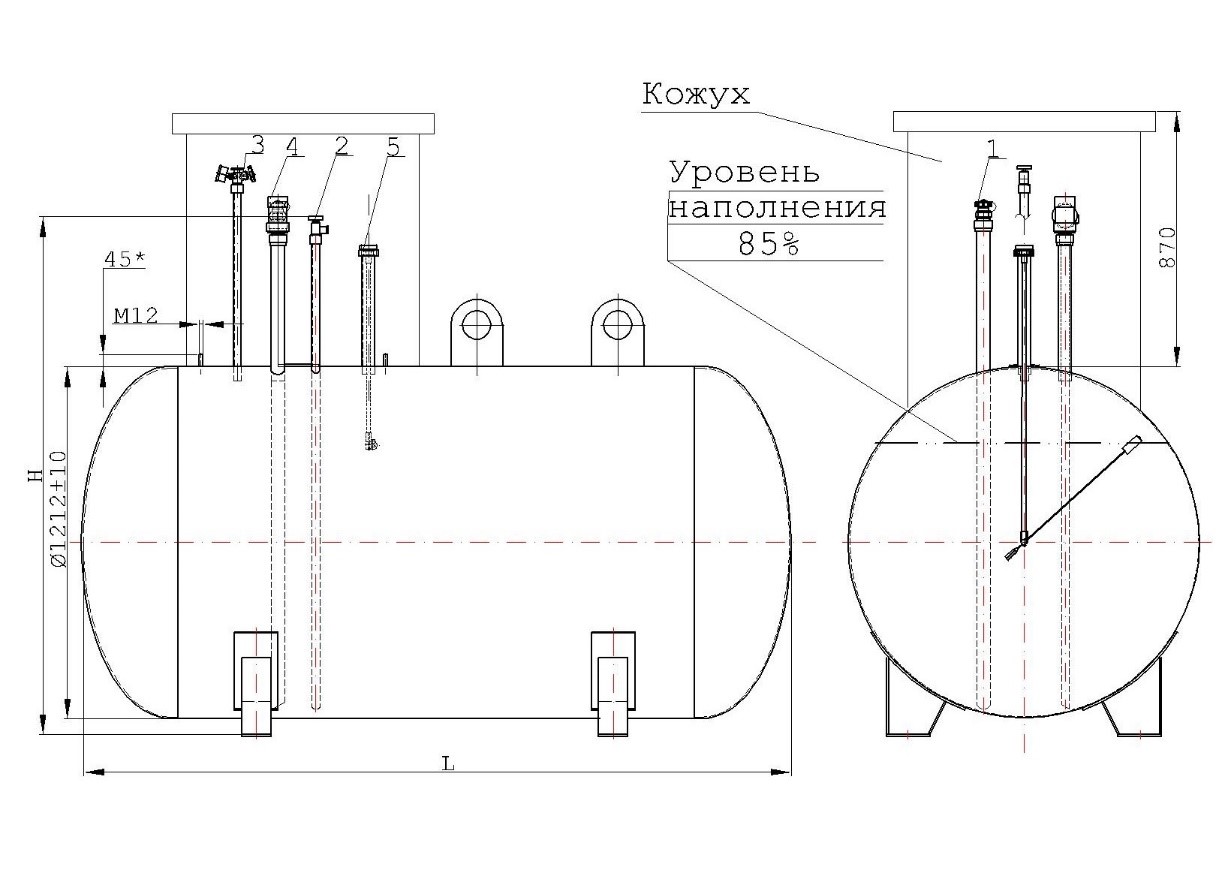

Underground LPG storage tanks

Standard equipment of BGZH gas tanks…-1200/16

Advantages of gas tanks LLC “Balcity”

- containers are certified;

- containers are produced on modern Italian equipment;

- shut-off valves of the reputable Italian company CAVAGNA Group are installed on the tank;

- 100% radiographic control of welded joints;

- thickness of steel 09G2S (5-6 mm) corresponds to GOST 34233.1-GOST 34233.1-2;

- anti-corrosion coating.

| Tank designation | Capacity, l | Overall length L, mm | Shell length, L1, mm | Outer diameter Dn, mm | Height H, mm | Metal thickness S, mm | Weight m±100, kg |

| BGZH 2200/1200-16 | 2200 | 2155±15 | 1480 | 445÷515 | |||

| BGZH 2700/1200-16 | 2700 | 2600±15 | 1925 | 510÷595 | |||

| BGZH 3100/1200-16 | 3100 | 2900±20 | 2220 | 555÷648 | |||

| BGZH 3900/1200-16 | 3900 | 3640±20 | 2960 | 665÷780 | |||

| BGZH 4800/1200-16 | 4800 | 4380±25 | 3700 | 775÷910 | |||

| BGZH 5600/1200-16 | 5600 | 5120±25 | 4400 | 1212±6 | 1960±50 | 5,0-6,0 | 885÷1045 |

| BGZH 6400/1200-16 | 6400 | 5860±30 | 5180 | 1000÷1180 | |||

| BGZH 6600/1200-16 | 6600 | 6050±30 | 5370 | 1030÷1215 | |||

| BGZH 7300/1200-16 | 7300 | 6600±30 | 4415 | 1110÷1310 | |||

| BGZH 8100/1200-16 | 8100 | 7340±35 | 5920 | 1220÷1445 | |||

| BGZH 8950/1200-16 | 8950 | 8080±35 | 6660 | 1335÷1580 | |||

| BGZH 9800/1200-16 | 9800 | 8820±45 | 7400 | 1440÷1710 | |||

| BGZH 10000/1200-16 | 10000 | 9560±45 | 8140 | 1550÷1840 |

Vapor Phase Selection Valve KPF-1 (multipurpose valve)

Purpose — to ensure safe selection of the vapor phase of gas from the LPG tank.

ECE UN approvals

| Specifications | Meaning |

|---|---|

| Working medium | Hydrocarbon liquefied fuel gas for municipal household consumption in accordance with GOST 20448-2018 |

| Working pressure, no more than | 1.6 MPa |

| Conditional bore 7mm | 7 mm |

| Input connection 1.1.1. 3/4” - 14 NPT | 3/4” - 14 NPT |

| Output connection | 885” - 14 NGO-LH-INT (or M22x1.5L) |

| Operating ambient temperature | -40°…+45 °С |

| Weight, no more than | 0,95 kg |

| Reliability indicators – mean time between failures, not less – average service life, not less | 10000 cycles; 12 years |

| Torque of force for screwing the valve into the neck of the cylinder | 220±40 Nm |

| The moment of force on the flywheel for hermetically closing the valve | 4,7Nm |

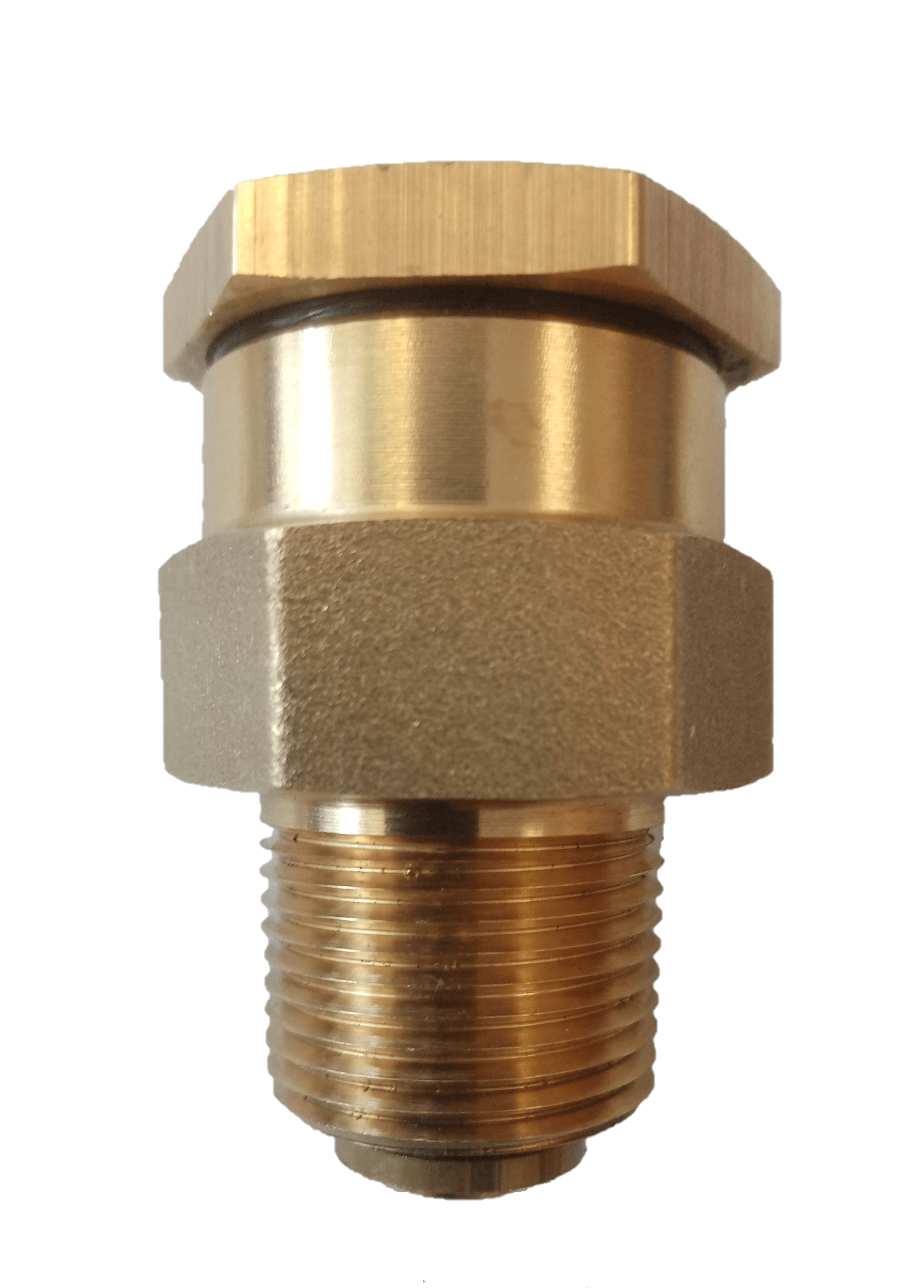

External safety valve KPn-2 and check valve (lower) KOn-2

The safety valve is designed for installation on tanks for liquefied hydrocarbon gases (LPG) to ensure that the gas pressure in the tank does not exceed the maximum allowable value.

The safety valve can be installed directly on the container or through a check valve.

The check valve makes it possible to replace the safety valve when the tank is full.

ECE UN approvals

| Parameter name | Safety valve KPn-2 | Check valve KOn-2 |

|---|---|---|

| Working environment | Hydrocarbon liquefied fuel gas for municipal household consumption according to GOST 20448 | Hydrocarbon liquefied fuel gas for municipal household consumption according to GOST 20448 |

| Working pressure (no more), MPa | 1,6 | 2,5 |

| P op - opening pressure (no more), MPa | 1,75 | - |

| P fo - full opening pressure (no more), MPa | 1,85 | 1 |

| Operating ambient temperature | -40°…+45°С | -40°…+45°С |

| Conditional bore, mm | 25 | 25 |

| Throughput at P but (not less), m3/min | 75 | 75 |

| Weight (no more than), kg | 0,8 | 0,5 |

| Input connection | 1” - NPT | 1 1/4” - NPT |

| Output connection | - | 1” - NPT |

| Reliability indicators: – mean time between failures (not less); - average service life (not less), years | 1000 cycles; 12 | - |

| Key size, mm | 55 | 46 |

| Screwing force moment, N∙m | 260±50 | 350±70 |

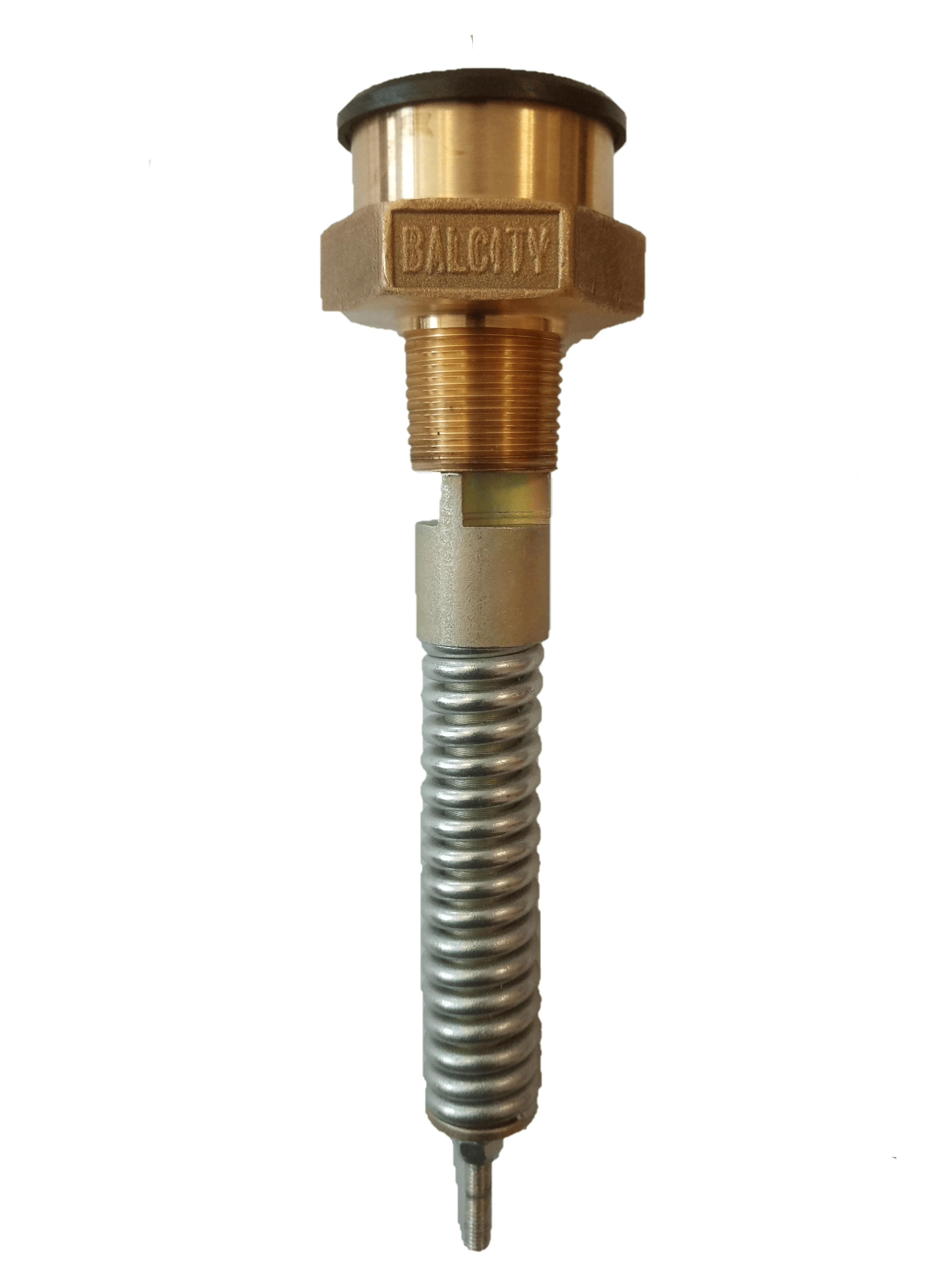

Filling Valve KN3

Filling valve KN3 TU 28.14.11-250-95158436-2021 is designed for installation on tanks for liquefied hydrocarbon gases in accordance with GOST 15860-84 and is their filling device.

Climatic version — U2 GOST 15150-69 (during operation in working condition, the lower value of the ambient air temperature is minus 40°C)

ECE UN approvals

| Specifications | Meaning |

|---|---|

| Working medium | Hydrocarbon liquefied fuel gas for municipal household consumption in accordance with GOST 20448-2018 |

| Maximum gas working pressure | 2,5 МPа |

| Regulated throughput of the valve at a pressure of 0.1 MPa | min 33.5 l/min |

| Operating ambient temperature | -40°…+45°С |

| Operating ambient temperature | К 1 1/4'' GOST6111 |

| Outlet thread | 1 3/4 - 6 ACME 2G outer |

| Weight | Not more than 0,55 кg |

| Reliability indicator – time between failures | At least 5000 cycles |

| Average service life | At least 12 years |

| Moment of force of screwing the valve into the neck of the container | (350±40) Nm |

| Wrench size | 46 mm |

Liquid Withdrawal Valve KZHF1

KZhF1 valve TU 28.14.11-250-95158436-2021 is designed for installation on tanks for liquefied hydrocarbon gases in accordance with GOST 15860-84 and is used to withdraw the LPG liquid phase.

Climatic version — U2 GOST 15150-69 (during operation in working condition, the lower value of the ambient air temperature is — 40°C)

ECE UN approvals

| Specifications | Meaning |

|---|---|

| Working medium | Hydrocarbon liquefied fuel gas for municipal household consumption in accordance with GOST 20448-2018 |

| Maximum gas working pressure | 2,5 МPа |

| Working ambient temperature | -40°…+45°С |

| Connection thread with tank | K 3/4'' GOST6111 |

| Outlet thread | K 3/4'' GOST6111 internal |

| Weight | Not more than 0,75 кg |

| Reliability indicator – time between failures | At least 5000 cycles |

| Average service life | At least 12 years |

| Moment of force of screwing the valve into the neck of the container | (220±40) Nm |

| Wrench size | 32 mm |

Drain Valve KS1

The drain valve KS1 TU 28.14.11-250-95158436-2021 is designed for installation on tanks for liquefied hydrocarbon gases in accordance with GOST 15860-84 and is used to drain the liquid phase of LPG and with extraneous contaminants.

Climatic version — U2 GOST 15150-69 (during operation in working condition, the lower value of the ambient air temperature is minus 40 °C)

ECE UN approvals

| Specifications | Meaning |

|---|---|

| Working medium | Hydrocarbon liquefied fuel gas for municipal household consumption in accordance with GOST 20448-2018 |

| Maximum gas working pressure | 2.5 MPa |

| Operating ambient temperature | -40°…+45°С |

| Connection thread with tank | K 3/4'' GOST6111 |

| Outlet thread | K3/4'' GOST6111 internal |

| Weight | not more than 0,35 кg |

| Reliability indicator – time between failures | at least 5000 cycles |

| Average service life | at least 12 years |

| Moment of force of screwing the valve into the neck of the container | (220±40) Nm |

| Wrench size | 36 mm |

Pressure Relief Valve type KP2

The pressure relief valve KP2 TU 28.14.11-250/1-95158436-2021 is designed for installation on tanks for liquefied hydrocarbon gases in accordance with GOST 15860-84 to ensure that the LPG pressure in the tank does not exceed the allowable value.

Climatic version — U2 GOST 15150-69 (during operation in working condition, the lower value of the ambient air temperature is minus 40°C)

ECE UN approvals

| Specifications | Meaning |

|---|---|

| Working medium | Hydrocarbon liquefied fuel gas for municipal household consumption in accordance with GOST 20448-2018 |

| Pressure of the beginning of opening of the safety valve (РНО), bar | No more than 16.67 |

| Safety valve setting pressure (RN), bar | Not less than 15.65 |

| Full opening pressure (RPO) | bar 17.65 |

| Capacity (G) at full valve opening (RPO) | not less than 71 m3/min |

| Operating ambient temperature | -40°…+45°С |

| Connection thread with tank | К 1'' GOST6111 |

| Weight | not more than 0,85 кg |

| Reliability indicator – time between failures | at least 100 cycles |

| Average service life | at least 12 years |

| Moment of force of screwing the valve into the neck of the container | (220±40) Nm |

| Wrench size | 44 mm |

Pressure Relief Valve KP1

The pressure relief valve KP1 TU 28.14.11-250/1-95158436-2021 is designed for installation on tanks for liquefied hydrocarbon gases in accordance with GOST 15860-84 to ensure that the LPG pressure in the tank does not exceed the allowable value.

Climatic version — U2 GOST 15150-69 (during operation in working condition, the lower value of the ambient air temperature is minus 40°C)

ECE UN approvals

| Specifications | Meaning |

|---|---|

| Working medium | Hydrocarbon liquefied fuel gas for municipal household consumption in accordance with GOST 20448-2018 |

| Pressure of the beginning of opening of the safety valve (РНО), bar | No more than 16.67 |

| Safety valve setting pressure (RN), bar | No more than 16.67 |

| Full opening pressure (RPO) | bar 17.65 |

| Capacity (G) at full valve opening (RPO) | Not less than 39 m3/min |

| Operating ambient temperature | -40°…+45°С |

| Connection thread with tank | K 3/4'' GOST6111 |

| Weight | Not more than 0,55 кg |

| Reliability indicator – time between failures | At least 100 cycles |

| Average service life | At least 12 years |

| Moment of force of screwing the valve into the neck of the container | (220±40) Nm |

| Wrench size | 44 mm |